- Phone : +91 8072836392

- Email : natesh95@hotmail.com

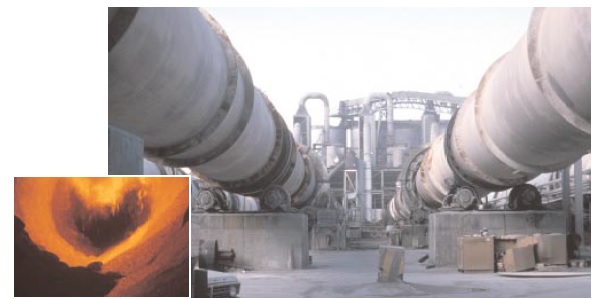

Steel Fiber Castable is produced by adding refractory steel fiber into the raw material to grant it a higher strength and thermal shock resistance, thus to finally increase its wear resistance capacity and service life. This Castable is mainly used in the high-temperature wearable parts such as kilneye, feed opening, the wearable pier and the lining of power plant boiler.

Application of Steel Fiber Castable

. Steel furnaces

. Iron making furnaces

. Glass kiln

. Ceramic tunnel kiln

. Cement kiln

Steel Fiber Castable Technique Data

Items | RS-F16 | RS-F16K | RS-F17 | |

Al2O3+SiC% | 110℃x24h | 70 | 75 | 80 |

Bulk Density g/cm 3 | 110℃x24h | 2.6 | 2.7 | 2.8 |

MOR MPa | 1110℃x3h | 11 | 12 | 13 |

110℃x24h | 11 | 12 | 13 | |

Cold Crushing Strength MPa | 1110℃x3h | 90 | 100 | 110 |

1110℃x3h | 90 | 100 | 110 | |

Linear Dimensional Change % | 110℃x24h | ±0.1 | ±0.1 | ±0.1 |

1110℃x3h | ±0.3 | ±0.3 | ±0.3 | |

Low cement refractory Castable mainly includes three types: high alumina refractory Castable, mulite refractory Castable, corundum refractory Castable. This series of Castable are featured with high strength, anti-scouring, anti-abrasive, and excellent performance.

With these characteristics, the low cement refractory Castable is widely used as linings in reheating furnace and other industrial furnaces.

Application of Low Cement Refractory Castable

1. Furnaces of metallurgy industry, heat treatment furnace.

2. Furnace of incineration of garbage, recirculating fluidized bed furnace.

3. Furnaces of chemical industry and construction industry.

4. Tundish lining.

Low Cement Refractory Castable Technique Data

Al2O3, % ≥ | 50 | 60 | 70 | 80 | 90 | |

CaO, % ≤ | 2.5 | 2.2 | 2 | 2 | 1.8 | |

Bulk density, g/cm3 ≥ | 2.35 | 2.45 | 2.5 | 2.6 | 2.95 | |

Cold crushing strength, Mpa ≥ | 110x24h | 20 | 25 | 30 | 30 | 40 |

1000x3h | 45 | 50 | 55 | 55 | 65 | |

1400x3h | 60 | 65 | 70 | 70 | 80 | |

Linear on reheating, % | 1400x3h | ±0.5 | ±0.4 | ±0.4 | ±0.3 | ±0.4 |

Max. service temperature, °C | 1400 | 1450 | 1500 | 1550 | 1650 | |

Water consumption, % | 6 ~ 7.5 | 6 ~ 7.5 | 6 ~ 7.5 | 6 ~ 6.5 | 6 ~ 6.5 | |

Silicon Carbide Castable are made from high-grade silicon carbide and industrial silicon powder as raw materials. Which is one of the unshaped refractory materials. It is made of refractory aggregate, refractory powder, binders and other additives. It is loose, no fixed shape,Has high liquidity, casting and vibration molding, can use directly or use after add appropriate water or other liquid. It is one of the new type refractory material of don’t need calcination.

Application of Silicon Carbide Castable

Silicon Carbide Castable mainly used for different parts of cement kiln and the roof of electric arc furnace and steel ladel.

Silicon Carbide Castable Technique Data

Quality | RS SICAST 85 | RS SICAST 80 | RS SICAST 60 | ||

Physical Properties | Required quantity (t/m3) | 2.68 | 2.6 | 2.5 | |

Water Required for Casting (%) | 6 – 7 | 6 – 7 | 7 – 8 | ||

CCS (kg/cm2) | @ 110℃x24h | 650(140) | 500(90) | 450(70) | |

@ 1000℃x3h | 850(150) | 600(150) | 550(100) | ||

@ 1350℃x3h | 1100(250) | 1000(250) | 1000(250) | ||

PLC (%) | @ 110℃x24h | -0.06 | -0.06 | -0.06 | |

@ 1000℃x3h | -0.1 | -0.1 | -0.2 | ||

@ 1350℃x3h | -0.1 | -0.1 | -0.12 | ||

TC (kcal/mh℃) | @ 350℃ | 11.5 | 11 | 8 | |

Chemical Properties (%) | Al2O3 | 9 | 9 | 20 | |

SiC + C | 83 | 78 | 58 | ||

Main Applications | Nonferrous Metal Furnace, Incinerator, Cement Furnace & other Industrial Furnace | ||||

Silica Refractory Castable are formulated for increased thermal shock resistance, low thermal expansion, and resistance to molten metal attack. Our Castables are manufactured using high quality calcium aluminate cement and high purity fused silica. Our fused silica Castables have seen extensive use in transfer troughs, stalk tubes, flow control components, liners, and launders. We have several insulating Castables and non-wetting Castables to choose from. All of our Castables are subject to a strenuous QC process.

Application of Silica Refractory Castable

Silica Refractory Castable are used in refractory Castables provides better particle packing. Silica fume use requires less water, while maintaining the same flow characteristics. also use promotes low temperature sintering, and the formation of mullite in the matrix of Castables.

Silica Refractory Castable Technique Data

| Si-1 | Si-2 | Si-3 |

Refractoriness | 1700 | 1600 | 1700 |

Binding time > | 1~2 | 1~2 | 2~3 |

0.2Mpa RUL °c | 1600 | 1420 | 1600 |

SiO2 | ≥94% |

| ≥96% |

Al2O3 |

| ≥85% | ≤0.6% |

Fe2O3 | ≤1.0% |

| ≤0.7% |

Grian size | | | |

Aplication | hot-blast furnace | coke oven | glass furnace |

Fire Clay Refractory Castable for aggregate with bauxite and flint clay, silica powder, calcium aluminate cement, water reducing agent prepared general Castable, choose corresponding grade aggregate, mixture volume density of 2.2 clay Castable for customers to use. The product compact structure, high temperature performance is good, good thermal shock resistance and abrasion resistance, construction is convenient, suitable for all kinds of neutral industrial kiln lining.

Application of Fire Clay Refractory Castable

Fire Clay Refractory Castable is used in the lining of steel rolling heating furnace,heat treatment furnace,boiler,shaft kiln,preheating zone of rotary kiln

Fire Clay Refractory Castable Technique Data

Index | Fire clay | High alumina 1 | High alumina 2 | |

Al2O3 % | 40-45 | 60-65 | 70-75 | |

SiO2 % | 35-40 | 23-30 | 15-20 | |

CaO % | 5-6 | 5-6 | 5-6 | |

Bulk density g/cm3 | 110°C,24h | 2.0-2.1 | 2.4-2.5 | 2.7-2.8 |

1350°C,3h | 2.1-2.15 | 2.5-2.6 | 2.7-2.85 | |

Bending Strength MPa | 110°C,24h | 4.5-6 | 5-6 | 5.5-6 |

1350°C,3h | 6-7 | 6.5-7.5 | 7-8 | |

Compressive strength MPa | 110°C,24h | 30-35 | 40-45 | 45-50 |

1350°C,3h | 45-50 | 50-60 | 55-65 | |

1350°C Reheating linear change % | +(0.1-0.3) | -(0.1-0.3) | -(0.1-0.5) | |

water content to mixture % | 10-12 | 10-12 | 10-12 | |

Service temperature °C | 1350 | 1450 | 1550 | |

Corundum Mullite Castable is a kind of high strength unshaped refractory materials for sale in RS Company, which can be used in cement kiln. Corundum Mullite Castable Refractory can perform high properties such as high crushing strength, high temperature stability, thermal shock resistance, wear and chemical erosion resistance in lining of large power station boiler and other high temperature equipments.

Application of Corundum Mullite Castable

Corundum Mullite Castable Refractory can be used in steel furnace, cement kiln, glass furnace, iron making furnace, ceramic tunnel kiln and so on.

Corundum Mullite Castable Technique Data

Item | RSCMC-1 | RSCMC-2 | RSCMC-3 | |

Al2O3 ≥ | 70 | 75 | 85 | |

SiO2 ≤ | 25 | 17 | 13 | |

Fe2O3 ≤ | 1 | 1 | 1 | |

Bulk Density g/cm3 ≥ | 2.7 | 2.8 | 2.9 | |

0.2MPa Refractoriness Under Load ℃ ≥ | 1450 | 1480 | 1500 | |

Thermal Shock Resistance, Times, (900℃, water-cooling) ≥ | 25 | 25 | 25 | |

Maximum Service Temperature ℃ | 1550 | 1550 | 1600 | |

Linear Dimensional Change % ≤ | -0.3 | -0.2 | -0.2 | |

Cold Crushing Strength Mpa ≥ | 110℃*24h | 100 | 110 | 120 |

1100℃*3h | 100 | 110 | 120 | |

1400℃*3h | 115 | 120 | 125 | |

MOR ≥ | 110℃*24h | 15 | 15 | 15 |

1100℃*3h | 16 | 17 | 18 | |

1400℃*3h | 17 | 18 | 19 | |

High Alumina Castable is a kind of refractory Castable which uses high alumina raw material as aggregates and the powder and then be added with binding agent. High aluminum refractory Castable has high mechanical strength, good thermal shock resistance, good corrosion resistance. It’s mainly used for furnace lining of boiler, blast furnace hot blast stove, heating furnace, ceramic kiln and various industrial furnaces.

Application of High Alumina Castable

High Alumina Castable also called calcium clinker, is made from industrial alumina oxide powder and selected limestone powder. It is produced after manufactured under high temperature in rotary and grind into powder. The product is for making high quality refractory Castables, which is a dispensable tool used in high temperature facilities in industries like metallurgy, building material, chemical, electric plant, etc.

High Alumina Castable Technique Data

Items | RSGLJ-1 | RSGLJ-2 | |

Al2O3 % | 65 | 75 | |

Refractoriness ℃ | 1750 | 1770 | |

Linear Dimensional Change % | -0.02 | -0.4 | |

Cold Crushing Strength MPa ≥ | 110℃×24h | 50 | 60 |

1100℃×4h | 60 | 70 | |

Breaking Strength MPa ≥ | 110℃×24h | 9 | 11 |

1100℃×4h | 10 | 12 | |

Maximum Service Temperature ℃ | 1200 | 1400 | |

Refractory Castable is an unshaped material delivered in the state of dry powder, and mixed before use, can harden at the ambient temperature to achieve adobe strength after construction without heating.

Light weight refractory Castable composed of refractory lightweight aggregate, powder, binder and admixture and other components. The product has characteristics of small volume, high compressive strength, good acid and acid gas corrosion resistance, good insulation performance, low water absorption. Its construction is simple, is the best construction product for the high temperature alkali resistant parts. Good workability, strong cohesion, initial setting time and construction can be a long time, fast strength growth, strong impermeability, no acidification, easy to ensure that the masonry plaster full and dense, can significantly improve the chimney liner air tightness, integrity and anti-corrosion ability. It is an ideal cementing material for high chimneys, high temperature flue and duct lining. It can also be used in acid tank and other acid resistant parts in petroleum, chemical, nonferrous metallurgy and so on.

Application of Insulation Refractory Castable

Lightweight insulating castabel is used for rotary kiln and industrial kiln for heat insulation or single-lager lining.

Insulation Castable Technical Data

Item | RS-0.5 | RS-0.8 | RS-1 | RS-1.3 | RS-1.5 | RS-1.8 | RS-2 | ||

Chemical Composition % | Al2O3 ≥ | 38 | 40 | 40 | 40 | 45 | 45 | 45 | |

Bulk density g/cm3 ≥ | 110°C,24h | 0.5±0.1 | 0.8±0.1 | 1.0±0.1 | 1.3±0.1 | 1.5±0.1 | 1.8±0.1 | 2.0±0.1 | |

Reheating linear change % | 1000°C,3h | -1.0~0 | -1.0~0 | -1.0~0 | -0.5~0 | -0.5~0 | -0.5~0 | -0.5~0 | |

Compressive strength MPa ≥ | 110°C,24h | 1 | 2 | 3 | 6 | 7 | 12 | 15 | |

1000°C,3h | 1 | 2 | 3 | 7 | 12 | 25 | 30 | ||

1350°C,3h | – | – | – | – | 20 | 30 | 35 | ||

Thermal conductivity W/(m.k) | 700°C | 0.15 | 0.25 | 0.35 | 0.4 | 0.65 | 0.7 | 0.75 | |

1000°C | – | – | 0.4 | 0.45 | 0.75 | 0.75 | 0.9 | ||

Service temperature °C ≥ | 1100 | 1150 | 1200 | 1250 | 1300 | 1300 | 1350 | ||

Follow us

Don’t get stuck with the rest, truck with the best.

Moving your products across all borders.